Music

Trailers

DailyVideos

India

Pakistan

Afghanistan

Bangladesh

Srilanka

Nepal

Thailand

StockMarket

Business

Technology

Startup

Trending Videos

Coupons

Football

Search

Download App in Playstore

Download App

Best Collections

Technology

Did all the good Shark Tank stories happen 40-plus years ago? No, of course not. Sharky is confident that IoT, for one thing, is going to be a treasure trove of great true tales of IT life. Itjust that right now you&re probably all too busy putting out the fires — and besides, time removes the pain and reveals the humor!

And so, once again, we hark back to the days of mainframes, one dominant vendor, and monstrous tabulating machines like the IBM 402. Pilot fish, who is much older and wiser now, was a college student at the time, working in a data processing department while studying for his degree in electrical engineering. The 402, recalls fish, was a behemoth, &stuffed full of pullies, fan belts, gears, relays, mechanical accumulators, card read stations, hammer print heads, wiring, more relays, delicate copper tubing supplying oil to all the bearings and a big motor driving everything.& Seriously, he asks, &when was the last time you operated a piece of computing equipment that had a built-in drip tray?&

To read this article in full, please click here

- Details

- Category: Technology

Read more: But what do you do with all your spare time

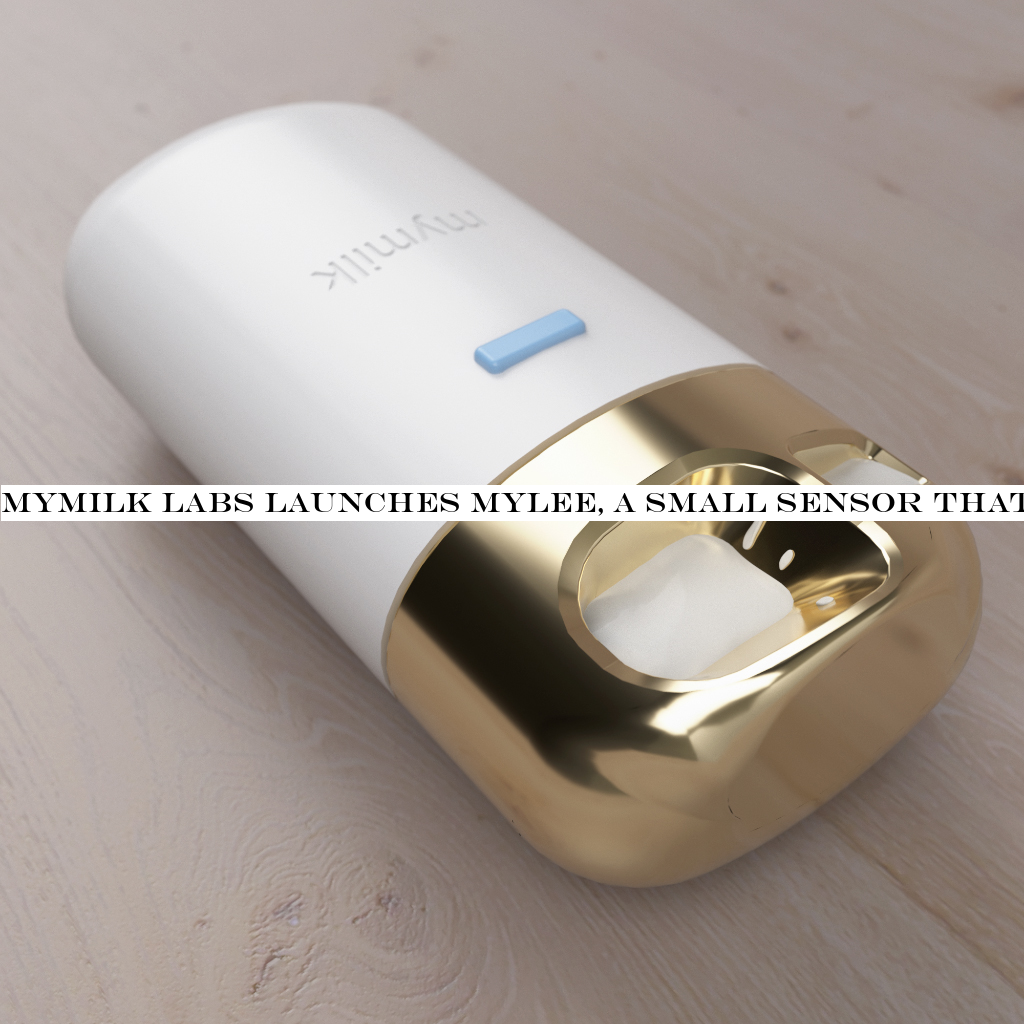

Write comment (92 Comments)Many expectant mothers are told that breastfeeding will come naturally, but it is often a fraught and confusing experience, especially during the first few weeks after birth. Parents often worry about if their babies are getting enough nutrition or if they are producing enough milk. MyMilk Labs wants to give nursing mothers more information with Mylee, a sensor that scans a few drops of breast milk to get information about its composition and connects to a mobile app. The Israel-based company presented today at Disrupt Battlefield as one of two wild card competitors picked from Startup Alley.

The Mylee launched at Disrupt with a pre-order price of $249 (its regular retail price is $349). Based in Israel, MyMilk Labs was founded in 2014 by Ravid Schecter and Sharon Haramati, who met while working on PhDs in neuroimmunology and neurobiology, respectively, at the Weizmann Institute of Science.

During the companystage presentation, Schecter said the device is meant to give mothers and lactation consultants objective information about breast milk.

During the companystage presentation, Schecter said the device is meant to give mothers and lactation consultants objective information about breast milk.

Breast milk changes in the first days and weeks after birth, progressing from colostrum to mature milk. Mylee scans the electrochemical properties of milk and then correlates that to data points based on MyMilk Labs& research to calculate where the sample is on the continuum, then tells mothers if their milk is &delayed& or &advanced,& relative to the time that has passed since they gave birth.

The devicefirst version is currently in a beta pilot with lactation consultants who have used them to scan milk samples from 500 mothers.

MyMilk Labs already has consumer breast milk testing kits that enable mothers to provide a small sample at home that is then sent to MyMilk Labs& laboratories for analysis. One is a nutritional panel that gives information about the milklevels of vitamins B6, B12 and A, calories and fat percentage, along with dietary recommendations for the mother. Another panel focuses on what is causing breast pain, a frequent complaint for nursing mothers. It tests for bacterial or fungal infections and gives antibiotic suggestions depending on what strains are detected.

Though some doctors believe testing kits are unnecessary for the majority of nursing mothers, there is demand for more knowledge about breastfeeding, as demonstrated by the line-up of breast milk testing kits from MyMilk Labs and competitors like Lactation Labs, Everly Well and Happy Vitals. Haramati said on stage that MyMilk Labs plans to eventually transfer some of the tests& capabilities to the Mylee.

- Details

- Category: Technology

Read more: MyMilk Labs launches Mylee, a small sensor that analyzes breast milk at home

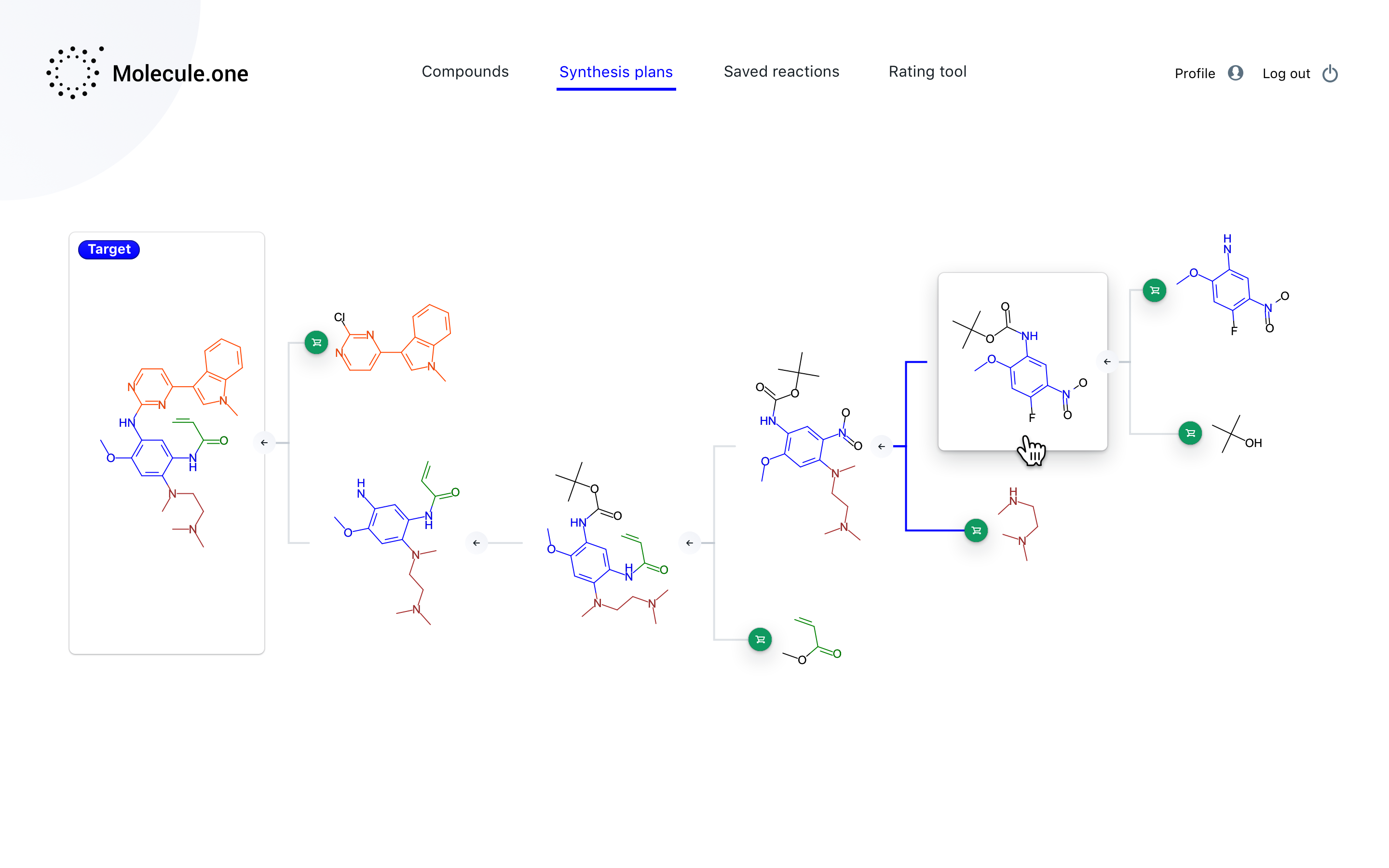

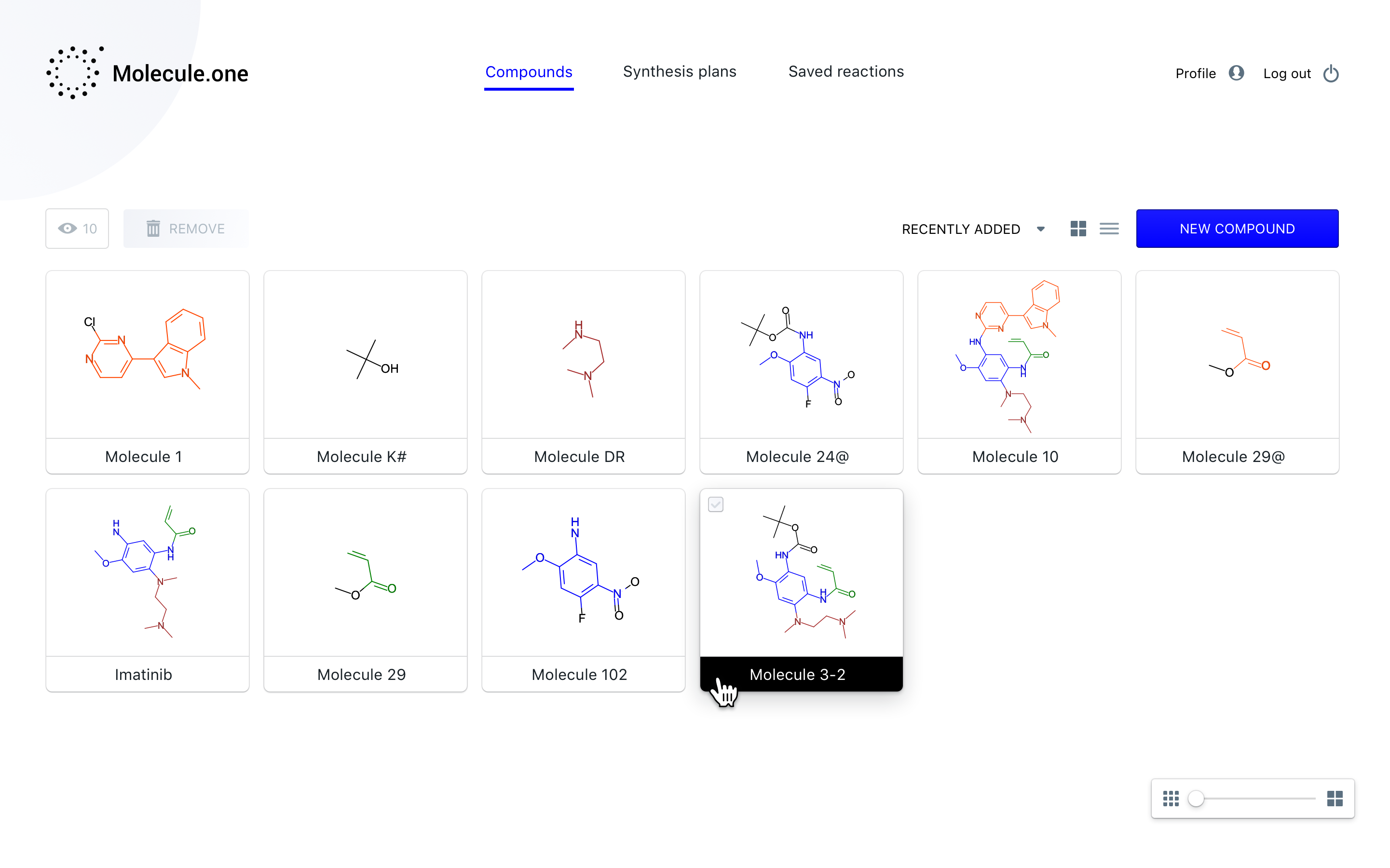

Write comment (95 Comments)Say you&re a pharmaceutical company. You&ve figured out that a novel molecule could be effective in treating an illness — but that molecule only exists in a simulation. How do you actually make it, and enough of it, to test in the real world? Molecule.one is a computational chemistry platform that helps bring theoretical substances to life, and it is debuting its product onstage at Disrupt SF Startup Battlefield.

Computational chemistry is, believe it or not, something of a hot ticket right now. The explosion in computing resources over the last decade has made it possible for the extremely complex systems of molecular biology to be simulated in high enough fidelity to produce new drugs and other important substances.

For example, say a company knows that a condition is caused by overproduction of a given protein. By simulating that protein in the soup of the cell environment, computational chemists can also introduce and virtually observe the behavior of thousands or millions of molecules that don&t occur naturally but might, say, lock down those excess proteins and tag them for removal by the cell.

This process of drug discovery has been productive, but unlike in the real world, in a simulation you don&t actually have to make that magical molecule. Itjust a bunch of numbers interacting with other numbers. How can a pharmaceutical company, which may have paid a lot of money for those numbers, turn them into actual molecules? Thatwhere Molecule.one steps in.

Essentially, the company has created a software platform that automates the process of getting from chemicals A, B, and C to chemical Z, with the many steps in between accounted for and documented. Itbased on a machine learning system that has ingested millions of patents and known chemical processes, allowing it to connect the dots and propose a method for creating pretty much any complex organic molecule. In other words, once a drug company has the &what& — a molecule or compound that may fight Alzheimer— Molecule.one provides the &how.&

Piotr Byrski met co-founder Paweł Włodarczyk-Pruszyński (who goes by Maxus to avoid confusion with COO Paweł Łaskarzewski) while in college, where they studied and did research together, eventually both earning MDs. They discovered a shared aversion to the grunt work of chemistry — beakers, distillates, titration, and so on.

&We found out we shared a similar analytical approach to chemistry. A lot of chemists really like the cooking process involved with organic synthesis,& Byrski told me. &I have to say… I never liked it very much. That made me think that there are many things in the everyday life of a chemist that can be automated, and need to be automated.&

&Automating organic synthesis seems like just another difficult automation problem, but itone with real effects. Real people are suffering because drugs are coming to the market,& he said. &We thought we could help. So we did some research, and we found that the field is so under-developed — the direction research is going is completely unsatisfactory. We began market research — we were both first timers so it was pretty new to us at the time — and we found out there was a big market need for this. It wasn&t a scientific discovery that would sit on a shelf, it could be applied today to help multiple industries.&

By the time they were working on this, companies were already applying simulation, and statistical techniques (machine learning is essentially weapon-grade statistical analysis) were already popping up. BenevolentAI started in 2013, Recursion in 2014, Atomwise in 2015; clearly the field was growing, and is still adding new companies, like ReviveMed. But these are mainly focused on the question of new drugs based on simulations.

&They provide a list of maybe tens of thousands of structures to a pharmaceutical company, but the company then needs to actually verify whether the predictions have any real-life backing. For that you need physical access to these molecules — just knowing the structure doesn&t cut it,& said Byrski.

Molecule.onesystem tells them how to manifest these structures.

&We are making the whole synthesis pathway, so going from compounds that are available to ones that you want,& said Włodarczyk-Pruszyński. &Along the way we need to solve many problems — there are many reasons why a reaction could fail. We want to tell users how to make compounds with the process with the highest chance of success.&

And succeed they have: &Our system works for structures that have never been seen before by any chemist,& Byrski said.

The obvious question is why these huge pharma companies, with their bottomless pockets and technical expertise, don&t put together their own synthesis platforms. It comes down to people.

&The most important factor is that ithard for a pharmaceutical company to hire machine learning specialists who have a deep background in chemistry. Over 90 percent of the people I know that work on this in the pharmaceutical business are chemists who have some training in machine learning. This is a difficult problem that requires coming at it from the opposite direction,& Byrski explained. &Our head of machine learning [Stanislaw Jastrzębski] is a PhD from the computational side, who would normally go to Google, Facebook or Microsoft. We&ve built a team that is unique in how it bridges the computational technology and chemistry.&

The databases used by Molecule.onesystems, surprisingly, are mostly public. The U.S. Patent office has tons of patents involving chemical processes — some important, some small, some obscure, some obvious, but all verified and presented formally. This was a gold mine sitting in plain sight, Byrski said. Or perhaps a box full of Lego pieces just waiting to be assembled into the right machine.

The main &proprietary& information they used was a private listing of commercially available chemicals and their prices. A molecule may have more than one pathway to reach it, after all, or perhaps thousands, and one might be cheaper than the others or involve fewer toxic reagents.

With strong results from public databases, they have a better chance of getting pharma companies to share their internal databases when signing up for the service.

The actual business is conducted SaaS-wise, naturally, and all the work takes place in the cloud. Therealso an enterprise tier that allows for on-premises operation, for companies that would rather not have their trade secrets anywhere but on company-owned infrastructure.

So far the company has bootstrapped, and currently has about $400K in the bank, which Byrski said should last them well into next year. &The biggest cost is people,& he said. &Developers, designers, chemists. We&re a software business so we don&t have a lot of other costs — we don&t have to hire a lab, for example.& So they are looking for funding to help hire and scale.

Itnot common in Poland to segue directly from medical school into a startup, Byrski admitted. But he and Włodarczyk-Pruszyński felt that this was too significant an opportunity to do good to pass up. With luck their platform will prove as popular as the drug discovery startups that helped make it necessary to invent.

- Details

- Category: Technology

Read more: Molecule.one uses machine learning to make synthesizing new drugs a snap

Write comment (96 Comments)The demand for orbital launches is increasing steadily, and the industry is nowhere near keeping up. Leo Aerospace thinks it can help with a launch technique thatmore efficient and requires far less infrastructure than an ordinary rocket: a hot air balloon. With a rocket attached to it, of course. It sounds wacky at first, but it could prove to be an economical and flexible way of getting to orbit.

Leo is originally out of Purdue, one of two such teams on stage this week at Disrupt SF Startup Battlefield. Co-founder and CEO Dane Rudy said they were looking into new and better ways to achieve orbit besides the traditional surface-based rocket approach.

&We found this really elegant solution that was actually tested in a rudimentary way in the 50s by the Air Force, which is launching rockets from an aerostat — a balloon,& he said.

&We found this really elegant solution that was actually tested in a rudimentary way in the 50s by the Air Force, which is launching rockets from an aerostat — a balloon,& he said.

Perhaps used to countering narrowed eyes and barely disguised incredulity at this point, he hastened to follow up.

&It actually worked really well for what it was designed for. The issue they ran into was that the U.S. shifted toward sending people to the Moon — so there just wasn&t a need for that technology in the Apollo program. But the rise in small satellites has created a huge demand tailored to these capabilities,& he said.

It turns out using a balloon has big benefits. A large amount of a rocketfuel and engineering is dedicated to pushing it from the ground, where the atmosphere is heaviest, to the thinner upper atmosphere, where drag and other issues are much less of a worry. By going the first few miles straight up in a balloon, much less rocket is needed to get into orbit, since you&re skipping one of the hardest parts.

The technique is more or less exactly what you&d imagine: A large balloon inflates and lifts the payload, a small rocket, to a designated altitude. Once there it aligns itself and… well, lifts off is perhaps the wrong term. But it ignites and exits the atmosphere at a planned trajectory and inserts the payload into orbit.

There are already air-launch systems out there that use planes rather than balloons, presenting their own challenges and advantages. Leo Aerospacemain draws are flexibility and cost.

&Our system is fully mobile — it doesn&t require any ground infrastructure,& said Rudy. &The whole thing fits into a regular shipping container.&

That means it can take off wherever and, perhaps more importantly, whenever the client chooses.

Right now the launch industry is expanding like crazy, both because of an increase in total launches and the rise of &ride-sharing,& where dozens of payloads share the cost of a single rocket. The cost goes down, but there are serious inconveniences.

&They don&t have much choice in when they launch or what orbit they&re going to. Therealso the complexity of having to ride with a bunch of other payloads on board — you have to compromise on timing and so on,& Rudy said.

While ride-sharing means many payloads will get to space that might not have a few years ago, it also means they might wait for years while the rest of the seats fill up and get ready to roll. With Leo itpractically Dominofor orbit.

Thatall great in theory, but the fact is no one has made a balloon-based commercial launch system. When the Air Force did it, it was pretty crude: The rocket was carried in a vertical position and shot right through the balloon when it went up. That kind of rules out reusing the balloon, but Leoentire business is founded on reusability, since that brings costs down immensely.

&That was one of the big problems we had to solve — the expense of the balloon itself; helium is expensive, and the envelope [i.e. the balloon material] is expensive and fragile,& said Rudy. &How do we make that zero stage, as we call it, reusable?&

Amazingly, they determined that tough, ripstop nylon and hot air were actually the best solution. Itremarkably close in principle to an ordinary recreational hot-air balloon, but with the slight difference that it has to fly up to 18 kilometers of altitude and carry a rocket with it.

&The difference is how do you control and command this sort of vehicle, integrate it into airspace, suspend the rocket beneath it and all that,& Rudy said. &All the stuff you have at Vandenberg Air Base for a launch — we have to make all that mobile.&

A bit like going from an ordinary car to a self-driving one, Leoballoon may be similar to the recreational type in its basic form, but the technical advances are in how it is controlled and tracked. They can adjust for wind, control the yaw and rotation, rise to a very precise altitude, and so on — naturally, all remotely and with partial autonomy.

The rocket doesn&t shoot through its balloon as before, but fires off at a mission-determined angle. 18 km closer to space, with far less air resistance to worry about, the three-stage rocket (two solid, then one non-cryo liquid) can be much smaller and have far less mass — requiring less than half the fuel to lift a given mass to orbit. To be specific, the system is specced to send 33 gross kilograms, 25 kg of payload, to a 550 kilometer orbit — or about twice that to 300 kilometers.

December saw the company performing reduced-scale tests at altitude, an important stepping stone to regulatory approval. The plan is to make their first full-scale suborbital launch next year with their first customerpayload on board. Orbital launches are planned for 2022.

Leo has gotten through Decembertests on a quite barebones budget for a space startup of about $520,000, through TechStars and a grant from the National Science Foundation. Thatgreat for a foundation, Rudy said, but full-scale tests and an eventual transition to commercial operations will take more than six figures.

An Air Force Small Business Innovation Research grant has opened the door to other government sources, and therebeen interest from that quarter in the non-orbital potential of the system, for instance high-altitude testing, mobile communications infrastructure, and so on. So already there are multiple eggs in multiple baskets — an attractive quality for investors.

&We&ve done all the foundational work,& said Rudy. &Now itjust about scaling up.&

- Details

- Category: Technology

Read more: Leo Aerospace provides bespoke rocket launches — from a hot air balloon

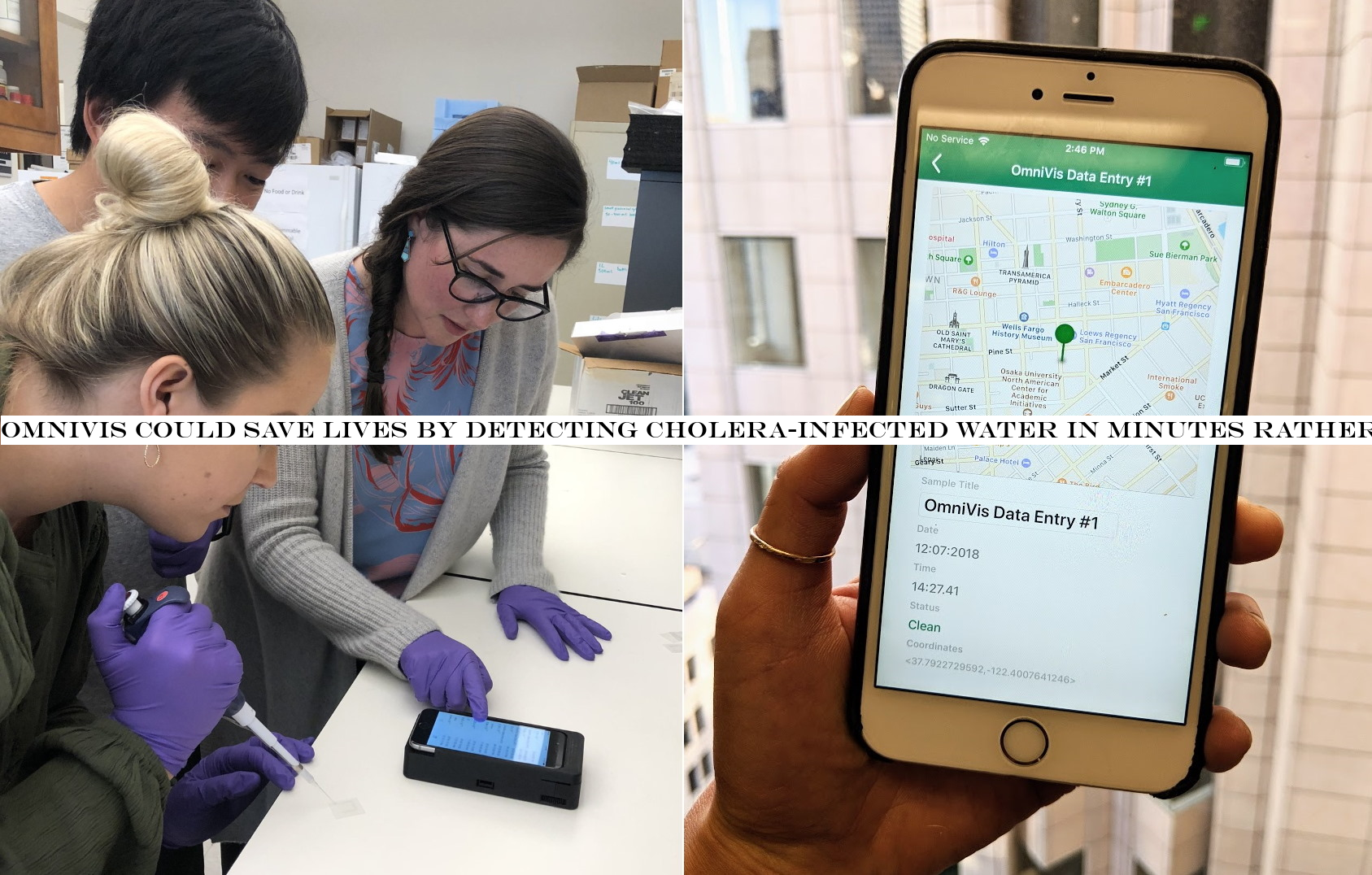

Write comment (92 Comments)Clean drinking water is one of the most urgent needs in developing countries and disaster-stricken areas, but safety tests can take days — during which tainted water can infect thousands. OmniVis aims to make detection of cholera and other pathogens as quick, simple, and cheap as a pregnancy test. Its smartphone-powered detection platform could save thousands of lives.

OmniVis, which presented on stage at Disrupt SFStartup Battlefield today, emerged from research conducted at Purdue University, where CEO and co-founder Katherine Clayton completed her doctorate. She and her advisors were working on the question of using microfluidics, basically very close inspection of the behavior of fluids, to detect cholera bacteria in water.

In case you forgot your Infectious Diseases 101, cholera is a bacterium that thrives in water polluted by fecal matter. When ingested it multiplies and causes severe diarrhea and dehydration — which as you might imagine can become a life-threatening problem if a community is short on clean water.

While normally uncommon, there was a huge cholera outbreak in Haiti in 2010 following a major earthquake there; 665,000 people were infected and more than 8,000 people died. It was this humanitarian disaster that prompted Clayton to look into how such an event might have been prevented. Shebeen working on what would become the OmniVis platform since 2013.

&Itbeen a long time coming,& she told me.

Thatnot uncommon for academic spin-offs with valuable IP but zero product experience. Moving from lab bench to field-ready hardware has taken years of hard work. But the resulting device could upend a costly and slow water testing process that leaves communities at risk in crucial moments.

Existing water testing is generally done at a central location, a lab run by a university, utility, or the local government. It depends on the region — and of course if there has been a disaster, it may not even be functional. Going from sample collection to results may take several days, and it isn&t cheap, either. Clayton estimated it at $100 per sample.

&But thatjust supplies and labor,& she said. &Not the cost of the lab, the PCR machines — which are tens of thousands of dollars — the pipettes, the dyes, the disposables and consumables, the training… not to mention in a lot of areas you&re not just going to walk by a nice central laboratory. Some countries may only have one or two testing facilities.&

Another option is disposable rapid diagnostic tests, more like pregnancy tests than anything, meant for use with stool samples — but their accuracy is low even then, and with cholera diluted in a water source you may as well be flipping a coin.

Such was the state of testing when Haiti had its outbreak and Clayton began looking into it. In 2013 they began investigating microfluidics as a method for detection. It works by exposing a set of chemical reagents, or &primers,& to a water sample. These primers are engineered to bind to bits of choleraDNA and then when heated, replicate it — a process called DNA amplification.

[gallery ids="1889722,1889720,1889721,1891113,1891110,1891105"]

The more cholera is present, the more DNA will be available to amplify, and it multiplies to the point where it affects the viscosity of the water — a factor that can be tested by the device. Interestingly, the device in no way &analyzes& the DNA or identifies it; all it does is measure how viscous the water is, which is a highly reliable proxy for how much cholera was present in it to begin with.

It turns out this method is both quick and accurate: In 30 minutes it gives as good or better results as central testing.

&The worst thing we could ever do is say thereno cholera in the water when there is,& Clayton said. So they&re focused on robust test results over all else. But ultimately the device still had to go from the lab to the real world. To that end the team conducted pilot tests in Haiti, where they worked with local NGOs and communities to get some direct feedback.

What they found was promising — but also resulted in major changes to the product. For one thing, they had to switch from iPhone to Android.

&People feel safer with Android than iPhone, which is considered a luxury item,& Clayton said. They also found that men and women operated the system equally well — the team is 84 percent women, she noted, and their design choices may have crept into the product the same as can happen on what is much more common, a male-dominated team. English and Svengali users likewise did fine. Interestingly, locals were baffled by roman numerals. &That was surprising,& she said, but illustrative of how even the smallest assumptions need to be questioned.

&I love user-centered design,& Clayton said. &I think itthe only way to get engineering to work. UX and graphic design is not my or my colleagues& specialty, so we had to get some outside contractors for that.&

The production device, which OmniVis hopes to ship in about six months, should cost around a thousand dollars — but at about $10 per test it will pay for itself quickly, especially considering how much easily it can be deployed and used. A half-hour turnaround on a test that can be performed by an aid worker with an hourtraining is an invaluable tool in a disaster-stricken area where infrastructure like mail and roads may be in disorder.

These devices, by the way, are not bought and paid for by the people who drink the water. Like the water-testing labs, they&ll be owned and operated by NGOs, governments and others with budgets for this kind of thing.

Cholera is the first pathogen the company is aiming to detect, but the system can just as easily detect several others simply by using different disposable tests equipped with different primers. E. Coli could be next — with the proper testing, Clayton said. And others would follow. Itnot hard to imagine an OmniVis device being a must-have for any relief work where water needs to be tested.

- Details

- Category: Technology

Read more: OmniVis could save lives by detecting cholera-infected water in minutes rather than days

Write comment (100 Comments)

Samsung this morning confirmed with Reuters that it has shuttered handset production in China. The move comes as the company continues to struggle in the worldNo. 1 smartphone market.

As we noted in a deeper dive into Chinasmartphone sales back in August, the Korean hardware giant has struggled to maintain a market share in the low single digits. Itnot alone, of course; Apple, too, has faced an uphill effort to crack the market, which is dominated by homegrown names, including Huawei, Vivo, Oppo and Xiaomi.

Sales have been driven by a combination of pricing and, in the case of embattled Huawei, patriotic purchasing decisions.

Samsung has slowly phased out production in the country over the past year, suspending operations in some plants, before ultimately pulling the plug altogether. The news follows a similar move by Sony. Apple, meanwhile, is maintaining its production in the country for now.

More recently, Samsung has looked to others countries, including India and Vietnam, which have undercut Chinaproduction costs. The company will, however, continue selling phones in China, even as it eyes other cheaper locations for manufacturing.

- Details

- Category: Technology

Read more: Samsung pulls the plug on Chinese smartphone production

Write comment (95 Comments)Page 739 of 5614

10

10